Bang Pa-In Industrial Estate

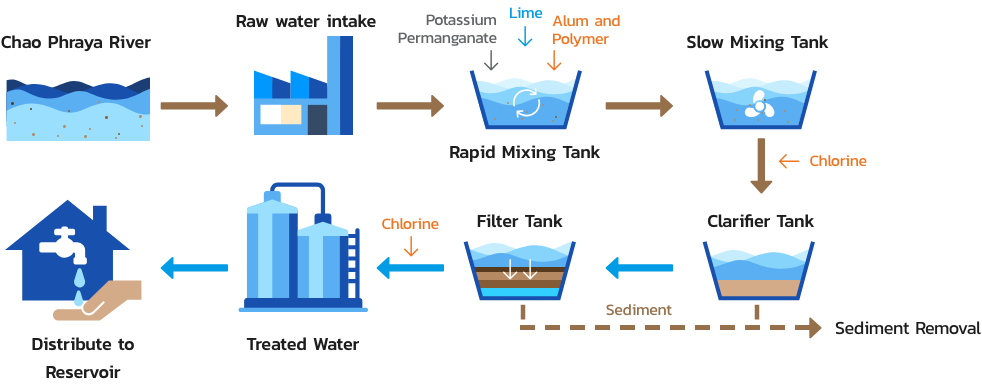

TTW PCL has already acquired the water production and wastewater treatment rights for Bang Pa-In Industrial Estate (BIE), Phra Nakhon Sri Ayutthaya, Bang Pa-In Land Development Co., Ltd. for a period of 30 years from August 2009 onwards. The water production system in Bang Pa-In Industrial Estate uses water from surface water sources, with the maximum production capacity of 48,000 cubic meters per day. Raw water is supplied from Chao Phraya River, with the average water production capacity of 18,000 cubic meters per day.

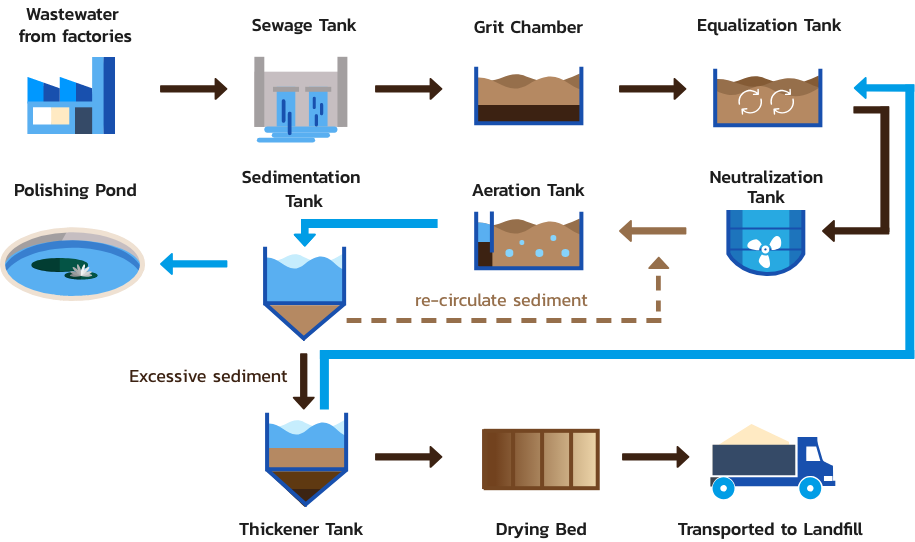

Bang Pa-In Industrial Estate’s central wastewater treatment system is an activated sludge system, with the treatment capacity of 18,000 cubic meters per day. Currently, the amount of wastewater is 14,000 cubic meters per day. Treated wastewater will be kept in the 18,000 cubic meter-storage pond (for a period of 1 day) before draining out to the Industrial Estate’s gutter to reuse, while the rest will be drained out to nearby water sources.

Wastewater from factories will be drained into

1. Sewage Tank

Wastewater from the 4 lift stations will be collected in the sewage tank of the central wastewater treatment system, where 3 sets of submersible pumps are installed; one of which is a spare one. They work in an automated manner, pumping wastewater to the grit chamber.

2. Grit Chamber

The grit chamber will separate gravel/sand in the wastewater, whereby the water flowing speed is controlled at around 0.3

3. Equalization Tank

The equalization tank will reduce the variance and the adjust quality of wastewater, whereby the storage period is 8-9 months (in a 7,000 cubic meter-tank). There are 6 sets of 5.9 kW and 3 sets of 7.5 kW submersible pumps installed in the tank, altogether 9 sets. They work manually, with the objective of pumping wastewater to the next process.

4. Neutralization Tank

This tank will facilitate the neutralization of acidity-alkalinity (pH) of the wastewater, by adding acidity if the wastewater is alkaline, or adding alkalinity if the wastewater is acidic, as well as adding required nutrients to the water for the effectiveness of the sludge treatment system. Within the neutralization tank, 2 sets of water dispenser and pH control device for the dispensing of the pH-adjusting chemical are installed (the devices are currently not in use because the wastewater’s pH value is neutral and the amount of nutrients is adequate).

5. Aeration Tank

Wastewater from the neutralization tank will be divided into 2 equal parts, before flowing to the 2 phases of aeration tank. It works by adding air (oxygen) into the wastewater so that microorganisms in the water both in the forms of solutions and organic matter-degrading suspended solids are decomposed.

6. Sedimentation Tank

The purpose of the sedimentation tank is to separate clear water from microorganisms. Water that has been treated will overflow the reservoir into the collection pipeline at the back of 2 phases of the aeration tank to the 4 sedimentation tanks, with the total capacity of 3,000 cubic meters. Sediment at the bottom of the tank will then be transferred to the aeration tank to decompose newly added organic matters, by installing the sediment pump and setting the right cycle time. Excessive sediment will be pumped into the thickener tank and be disposed of later.

7. Polishing Pond

The pond’s capacity is approximately 12,000 cubic meters, with the storage duration of about 16 hours. It is a resting place for treated wastewater before draining out to canals surrounding the Industrial Estate. Six sets of jet aerator were installed in the pond to increase the amount of dissolved oxygen (DO) in the water.

8. Thickener Tank

Excessive sediment from the wastewater treatment system both from the aeration tank and thickener tank will be transferred to the gravity sludge thickener in order to increase the concentration of the sludge to be not less than 2% to reuse it in the aeration tank or transfer it to the drying bed to separate sediment from clear water.

9. Drying Bed

The drying bed is a place where the sediment pumped out from the thickener tank will be dried before being disposed of. Dry sediment residue will be buried in a hygienic way as prescribed by law. There are 17 drying beds and each one can accommodate approximately 50-60 cubic meters of sediment. The drying period takes about 15 days.